Water Chiller

High technology sophisticated machines require chilled water circulation between 5°C to 15°C temperature, water chillers are built to maintain the above temperature for the continuous and smooth working of these machines. Special Stainless Steel (PUF / RUBBER insulated) tank provided in the unit prevents thermal losses. These chillers are constructed with highly reliable Compressors, Condensers and Evaporator Coils & Digital Temperature Controllers etc.

Oil Chiller

We bring forth for our clients an exclusive range of Oil Chillers that is considered for modern machine tool provided with hydraulic power packs. When the temperature of the hydraulic oil in the power pack is kept under control, the operating efficiency and accuracy of these machines are excellent. For maintaining continuous smooth operation of any machine tool, the normal temperature should be 35°C to 40°C. The specially designed refrigeration type oil coolers offered by us are required in maintaining a temperature in oil sumps. Our professionals manufacture these chillers using high-grade condensers, evaporator, compressors and temperature controllers.

Panel Air Cooler

Electronic Control Systems installed in CNC machines which generate heat during operation. Apart from heat, moisture laden air and dust also adversely affect electronic control. In order to maintain clean air environment required in electronic cabinets. Our Panel Air-cooler are manufactured with a closed loop design, these locks out excessive high ambient temperature, moisture and dust. The clean air within the cabinet is continuously cooled by the refrigeration system and re-circulated. The electronic components thus come into contact only with clean cool air. Hence, operating temperature within the cabinet can be maintained at 28°C to 30°C.

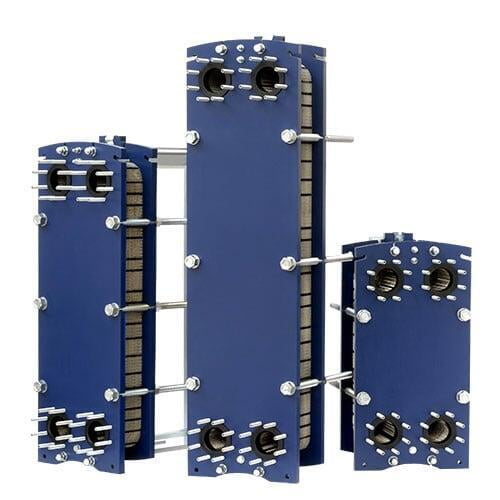

Heat exchanger

Heat Exchanger is an efficient device to heat or cool liquids by means of a heating or cooling media as the case may be. The most commonly used Heat Exchangers are the Shell and Tube type. The main feature of all the types is that the two liquids exchange heat without coming into direct contact with each other. There is no mixing of the two liquids and are separated by a metallic wall, the Heat exchange takes place by a combination of CONVECTION and CONDUCTION. There are many types of Heat Exchangers, the important types being the following.